Generative AI in Manufacturing: Benefits, Risks, and Future

The industrial sector is on the brink of a transformative era, thanks to the disruptive potential of artificial intelligence. As we witness the rapid evolution of Generative AI, a subset of AI, its potential to revolutionize the manufacturing industry is becoming increasingly clear. Generative AI is set to automate and enhance processes, enabling strategic decision-making at every stage.

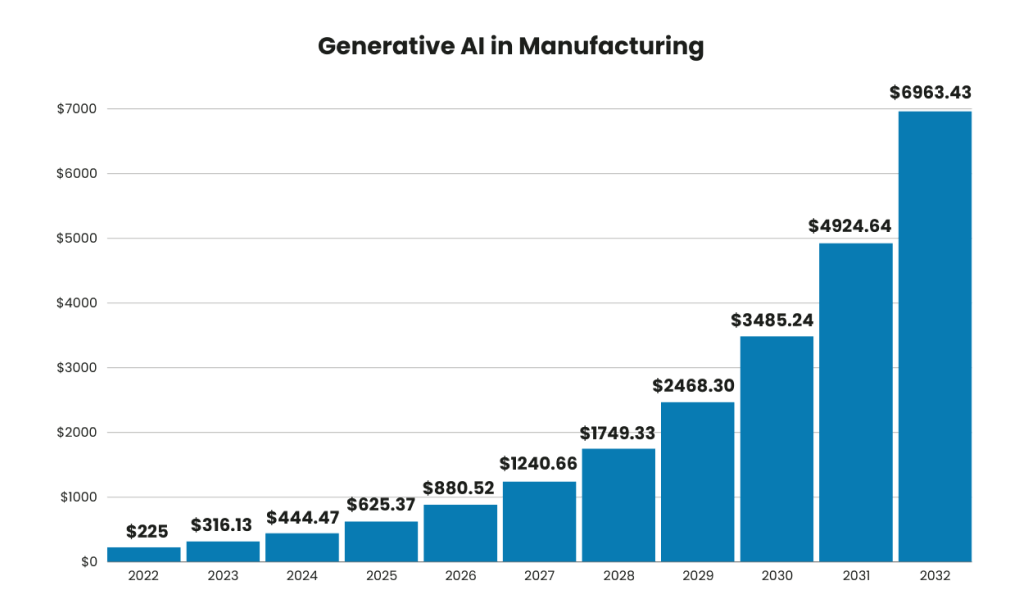

The report indicates that the Generative AI market is set for a rapid transformation of the manufacturing industry. With a predicted market value of USD 6,398.8 million by 2032 and a staggering compound annual growth rate (CAGR) of 41.06% from 2023 to 2032, the time to adapt to these changes is now.

In this blog, we will delve into the practical applications of Generative AI in manufacturing, including its advantages, challenges, and solutions. We will also provide a comprehensive step-by-step guide for implementing Generative AI in manufacturing, ensuring that you are well-prepared for the future of the industry.

The State of Generative AI in the Manufacturing Sector Right Now

Generative AI creates more than simply waves; it opens up a whole new world of possibilities. Consider this: in addition to being a tool, it is now the brains behind the scenes, bringing in a plethora of fresh ideas and streamlining processes.

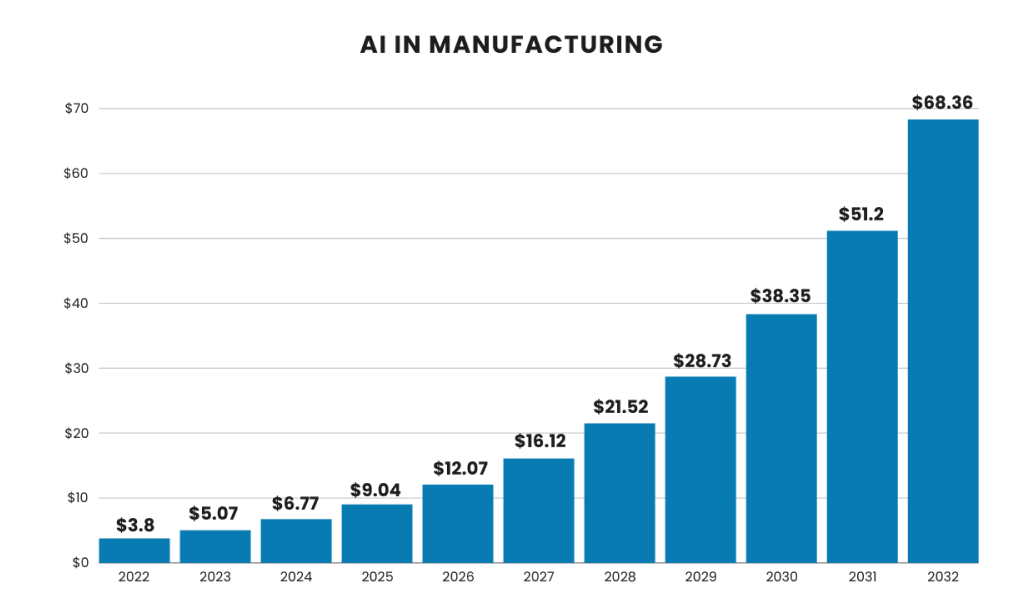

The exciting part comes next: by 2032, the market for AI in manufacturing will grow to an incredible USD 68.36 billion.

These astounding numbers indicate that we may surpass current technical breakthroughs and competition. We can do this with generative AI as a co-pilot for cooperation, which is akin to combining machine speed with human ingenuity.

What Is Generative AI in Manufacturing?

Generative AI in manufacturing refers to artificial intelligence systems that use patterns they discover in existing data to produce new content. In manufacturing, Generative AI, often powered by Large Language Models (LLMs) and Natural Language Processing (NLP), evaluates large volumes of data, simulates various situations, and provides creative solutions that can influence a variety of production processes.

Large Language Models (LLM)

Generative artificial intelligence models known as large language models (LLMs) are trained on vast amounts of text data, commonly known as a corpus. They have been used in a variety of fields, including text production, machine translation, and natural language processing since they can comprehend and produce text similar to that of a person.

Robust security and permissions, along with unique, pre-trained, fit-for-purpose LLMs, are essential for generative AI solutions in the industry. Industrial LLMs use operational data, training and workforce management data, linked worker and engineering data, and information from corporate systems.

Natural Language Processing

The study of computer-human natural language interaction is the focus of the artificial intelligence field known as natural language processing, or NLP. It entails the creation of models and algorithms that allow computers to comprehend, interpret, and react to human language in a meaningful and practical manner.

NLP is a crucial component of generative AI, allowing the assistants to comprehend and produce language that is human-like. This allows for smooth conversational user experiences and valuable support for managers, engineers, and frontline workers in manufacturing and industrial environments.

With the use of natural language processing and interpretation (NLPs), artificial intelligence (AI) can converse with humans. It can comprehend user inquiries, and respond with pertinent and precise information. Meanwhile, this information is required in common manufacturing operations like quality control, predictive maintenance, documentation review, and real-time support.

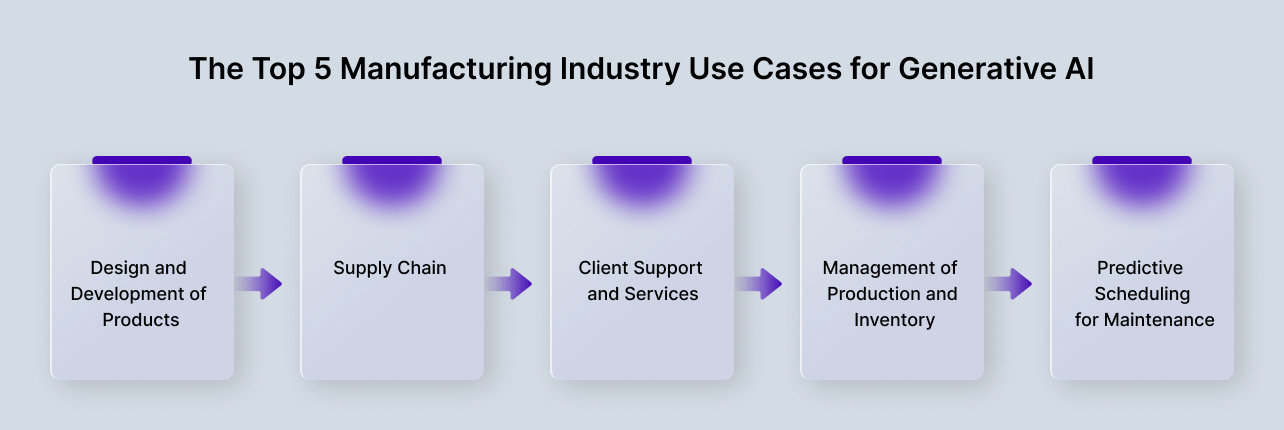

The Top 5 Manufacturing Industry Use Cases for Generative AI

The firm is constantly under pressure to improve manufacturing procedures and streamline supply chains. On the other hand, it can help provide clients with high-quality goods, and react swiftly to shifting market trends. The use of generative AI becomes very tempting in order to overcome these obstacles and encourages highly productive, networked, and intelligent industrial processes.

Understanding the practical applications of generative AI in relevant operations is essential to integrating its capabilities in manufacturing shrewdly. In this part, we have discussed the application cases of Gen AI in manufacturing.

Design and Development of Products

Everything in the manufacturing process is focused on goods, including designing, producing, and serving. The faster and more agile nature of generative AI integration greatly impacts product engineering. Moreover, the technology can help in the fundamental process of creating new goods or continuously improving ones that already exist.

By defining crucial criteria inside the model, generative AI in the manufacturing sector enables product engineers to forego laborious research and concentrate only on design. GenAI makes use of sophisticated algorithms to provide a variety of conceptual design possibilities and automate design optimization. Moreover, it can facilitate accurate testing, and assist in producing ideal product solutions that are ready for the future.

It allows engineers to carefully monitor, assess, and refine ideas before production starts by creating lifelike 3D models, digital twins, and simulations of product performance in design or virtual format. Therefore, AI offers a complete solution for developing and constructing reliable, customized products.

Supply Chain

GenAI’s capacity to evaluate data and produce information in various forms, including text, photos, and videos, is revolutionizing supply chain management. Disruptions to the supply chain pose serious problems for the industrial industry.

Manufacturers have a tremendous deal of visibility across interrelated components thanks to GenAI. It also offers value by analyzing various parameters, such as cost, availability of raw materials, possible dangers, etc., to suggest and choose providers. Moreover, the connection is strengthened by knowledge gained from previous contacts with suppliers. In order to guarantee seamless transactions and enhance the decision-making process, it provides real-time information into ongoing supply chain performance.

Client Support and Services

Generative AI, and large language models come together to redefine customer services. Chatbots and virtual assistants with GenAI capabilities facilitate faster customer interactions by tailoring interactions to each individual’s requirements. It guarantees prompt problem resolution, evaluating client inquiries, and offering precise, detailed troubleshooting instructions.

With the development of LLM, GenAI can now converse more naturally and human-like with clients. The system may work around the clock, answering reviews and addressing frequent questions from clients about invoicing, refunds, swaps, and purchases, among other things. Furthermore, this revolutionary technology may function as the manufacturer’s agent to improve customer satisfaction and effectively handle field queries.

Management of Production and Inventory

Optimal resource allocation and inaccurate inventory management are the leading causes of cost overruns in the manufacturing sector. A few significant issues that contribute to the process’s inefficiency include:

- Overstocking and out-of-stock scenarios.

- Need for improvement in demand forecasting.

- A need for insight into inventories.

Generative AI is essential to efficient production and inventory control for the industrial sector.

The GenAI model may examine market trends, previous sales data, and other essential variables. These insights enable manufacturers to optimize their manufacturing processes to meet the changing needs of stock. It directly fosters trust in their operations. The use of GenAI in production planning facilitates the achievement of optimum resource allocation, workflow optimization, and production scheduling.

Predictive Scheduling for Maintenance

When even the most sophisticated machinery and equipment are integrated, the production workflow’s complicated structure is strengthened. Machine breakdowns and failures are a typical occurrence in this fast-paced corporate environment, impeding all associated processes and causing consumer displeasure. Predicative maintenance is the most effective strategy for addressing this inefficient distribution that interrupts other area activities.

The combination of IoT and generative AI in predictive maintenance might revolutionize the way industrial organizations handle equipment maintenance. Strategically implementing predictive maintenance might be difficult because of the abundance of data and the need for more skilled data scientists. However, by automating data analysis and creating synthetic datasets, generative AI in manufacturing makes it possible to overcome all of these issues.

With the use of well-planned scheduling and predictive maintenance driven by generative artificial intelligence, the industrial sector may effectively reduce costs and limit downtime. Gen AI is an effective tool for predictive maintenance because it can learn from preexisting information and provide fresh insights.

Integrate Intelligent Gen AI into Operations to Modernize Them

Our team of professionals can use generative AI to overhaul your manufacturing company and revolutionize your production line.

Principal Advantages of Using Generative AI in the Manufacturing Sector

In the industrial sector, generative AI is a potent force that makes completely automated factories and efficient operations possible. Its capacity for increased integration enables it to spot inefficiencies and provide insightful information about every facet, including client relations, supply chain management, and manufacturing. This technology, which maintains high levels of productivity and efficiency throughout processes, represents industry 4.0 and intelligent manufacturing in the future.

In this section, we will go into further detail about the main advantages of generative AI in manufacturing.

Increased Efficiency & Productivity

Automating repetitive jobs in industrial processes, such as inventory management, supply chain operations, order processing, quality inspection, and having human-like discussions with clients/customers, is made easier with the use of GenAI. Gen AI frees manufacturing resources for strategic and value-adding activities by automating labor-intensive processes. Furthermore, it is simple to achieve greater efficiency when the workflow is optimized, and there is improved control and visibility over processes.

Astute Conserving

The best way to realize generative AI’s potential is to use it as a cost-cutting measure in the industrial sector. Indeed, operations may profit from the optimization of operations and cost reductions that come with incorporating Gen AI. Before making significant adjustments, manufacturing executives may use this technology’s capacity to identify bottlenecks and allocate resources efficiently. Using a trial-and-error methodology, engineers may save time and money by combining GenAI technology with digital twins.

The analytical abilities of Gen AI may prevent expensive interruptions brought on by repeated outages. It lowers expenses by monitoring and resolving equipment issues before they worsen. The manufacturing sector may manage inventory levels to prevent waste by accurately anticipating market trends and demand changes. All things considered, Gen AI provides a highly lucrative and sustainable manufacturing environment that will set the standard for future competitors.

Data-Informed Decision Making

More intelligent, data-driven decision-making is one of generative AI’s main advantages in production. Gen AI and data analytics provide advantages above conventional data analytics, enabling the management hierarchy to find intricate correlations and hidden patterns in the information. Making strategic choices in a variety of manufacturing domains, including supply chain management, inventory control, quality assurance, production planning, and scheduling, is facilitated by the availability of precise real-time information.

Enhanced Quality of Product

Manufacturers can assess and detect flaws in real-time using Generative AI, which can be trained on massive volumes of visual inspection and product quality data. This feature guarantees a quick turnaround in the rectification procedure, significantly minimizing waste.

Massive dataset analytics capabilities enable workers on the floor to evaluate production data and develop product quality prediction models. It makes it possible to make proactive changes that preserve consistency and avoid errors. AI can also reduce variability and improve product consistency by using simulations to optimize manufacturing parameters and determine the best settings for high-quality output.

Overcoming Manufacturing Industry Difficulties with the Use of Generative AI

Every organization involved in producing structures continues to face specific persistent difficulties. In this part, we’ll discuss the difficulties the manufacturing sector has implementing tech-enabled solutions and how generative AI makes those difficulties easier to overcome.

Information Administration

Challenge

The industrial sector produces enormous volumes of data every day as a result of its continuous operations. Keeping this disorganized data organized and generating valuable insights are still key issues. This complicates things and forces engineers to deal with problems like missing numbers and poor data quality.

Solution

The solution is for product and process analysts to use generative AI models such as variational autoencoders (VAEs) and generative adversarial networks (GANs) to manage mission values and quickly correct noisy or incorrect data in their datasets.

Skills of the Workforce

Challenge

As industrial processes incorporate new technologies on a regular basis, there is a growing disparity between the workforce’s proficiency and the technology’s execution.

Solution

To upskill the industrial workforce and provide interactive learning resources like virtual simulations, generative AI models help create synthetic training data. Additionally, they automate report production, offering data-driven insights and suggestions, relieving data analysis of some of their effort, and enabling frontline staff to make well-informed decisions.

Protection of Intellectual Property and Data Privacy

Challenge

Protecting intellectual property and sensitive data in the face of growing AI integration is challenging.

Solution

Generative models may reduce the need to communicate sensitive information and reduce the danger of theft or unauthorized use by producing synthetic, anonymized datasets and innovative designs, prototypes, and new concepts.

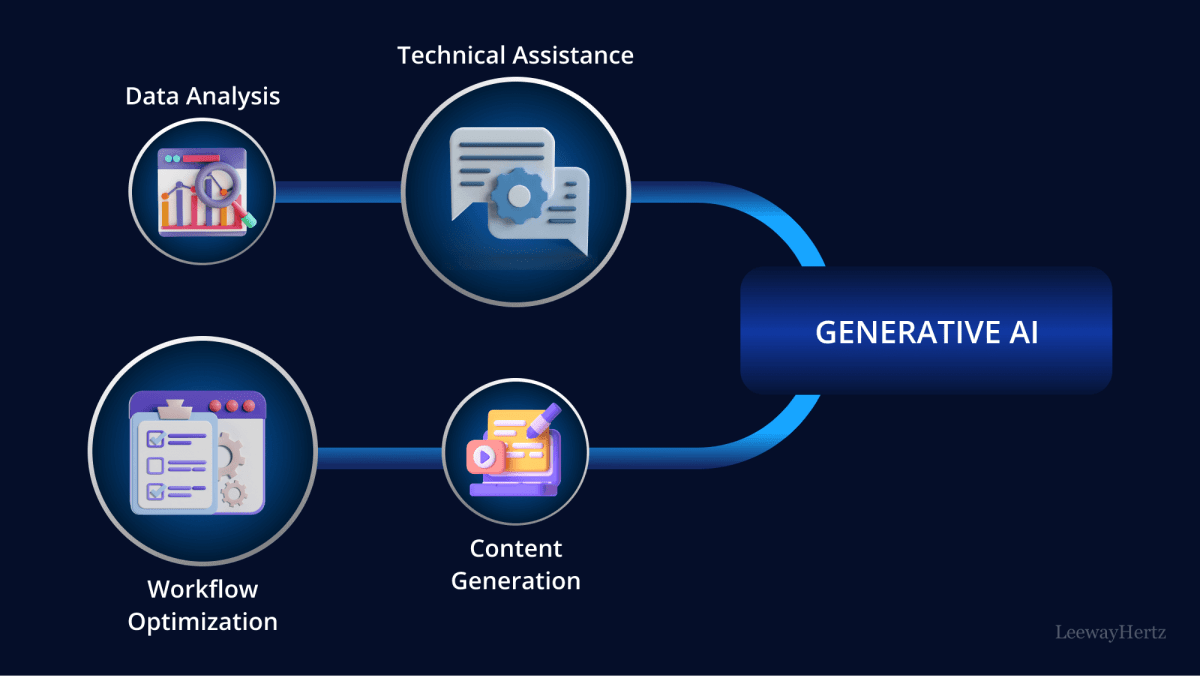

How Can Generative AI can Help Manufacturing Workflow?

Effective integration is critical to realizing the potential of generative AI in corporate processes, which may provide substantial gains in productivity, efficiency, and cost reduction. To successfully integrate Gen AI into industrial operations, enterprises must exercise more caution and adhere to a structured approach.

Here, we’ve covered a step-by-step procedure for using generative AI to manufacture successfully:

- Assess current workflow and processes, pay close attention to pain areas by carrying out a detailed analysis to find inefficiencies, bottlenecks, and quality problems, and comprehend how GenAI effectively integrates to solve them.

- Prioritize industrial processes and activities that stand to gain the most from GenAI integration, and explicitly define the goals, output, and key performance indicators (KPIs) to help you pre-determine particular use cases.

- This stage entails locating and processing pertinent data sources, such as production data, sensor readings, and maintenance records, to maintain data quality, cleanliness, and uniformity.

- Choose and create GenAI models by assessing and selecting the suitable algorithms and architectures that most closely match the defined use cases. Then, work with data scientists and subject matter experts to train and optimize the models.

- Create the required infrastructure, APIs, and user interfaces, then seamlessly integrate the trained models into the relevant processes to incorporate GenAI into manufacturing workflows.

- Establish reliable feedback systems to measure performance, evaluate results, and iterate on integration techniques and models to optimize benefits. This will allow you to monitor and continually improve.

- You can cultivate a culture of adoption and cooperation by involving cross-functional teams, advancing awareness and acceptance of GenAI. It can foster cooperation between domain experts and data scientists for ongoing innovation.

Manufacturing’s Use of Generative AI in the Future

Without question, GenAI has the potential to change the industrial sector altogether in the future. Gen artificial intelligence (GenAI) has the power to transform the industry and spur creativity. It is because of its enormous data analysis capabilities and insightful generation abilities. All things considered, there is a bright future ahead for GenAI’s impact and use in manufacturing, with a plethora of advantages and applications being investigated.

As with any new technology, GenAI in production is not without danger. GenAI offers serious hazards to individuals and organizations, ranging from the possibility of biased or enormous findings. It can happened if algorithms and machine learning models are not adequately trained or verified to the automation-related loss of human labor. It’s crucial to remember that there are ways to lessen the likelihood of these issues.

Generic artificial intelligence (genAI) has great promise to transform the industrial sector via its capacity to provide quick insights, improve operations, and stimulate innovation. Manufacturing companies may get a competitive edge in their respective industries by adopting this technology and managing the risks involved.

Why Choose Mtoag Technology as Your Partner for Tailored Generative AI Products in Manufacturing?

Leading AI/ML service provider Mtoag technology guarantees that your manufacturing processes develop in tandem with technology breakthroughs by providing solutions designed for continuous development. Because we are aware of the possibilities and difficulties facing the sector, we are able to create an AI-powered solution that specifically meets your particular set of demands.

Our generation AI services are intended to boost digital transformation by streamlining various industrial processes. It directly increases efficiency and lower running costs, giving your company a competitive advantage in the marketplace. Our knowledgeable team of Gen AI experts provides all-encompassing assistance and teamwork. Join Mtoag Technology to revolutionize your company’s operations in the future.

Concluding Remarks on Manufacturing Utilizing Generative AI

Artificial intelligence, which is revolutionizing the industrial sector, has ushered in a new era of unmatched efficiency, creativity, and profitability. Manufacturers may improve their maintenance practices by using AI. The technology helps detect abnormalities and errors early on and take appropriate action to prevent problems from getting worse. As a consequence, there is less downtime, longer equipment lifespans, and significant repair and maintenance cost reductions.

All signs indicate a future in which artificial intelligence (AI) will play a crucial role for success in production and manufacturing, with several application cases. Moreover, generative AI in manufacturing is equally important in this situation. Meanwhile, Astute businesses have already included AI in their maintenance processes and are seeing positive results. If they use complementary implementation to ensure a seamless transition, even small-scale firms may successfully integrate AI into their operations.

Frequently Asked Question

What is the future of GenAI in manufacturing?

GenAI’s future impact on manufacturing is enormous. It can smoothen out end-to-end production flows and foresee equipment failures before time. At the same time, it also monitors quality by detecting anomalies and supply custom experiences for buyers. With the evolution of GenAI, it will increasingly integrate into different parts of manufacturing which will have effects like efficiency driving productivity and innovation

What is an example of generative AI in manufacturing industry?

One example of generative AI in the manufacturing sector involves using generative models to generate fake data for training machine learning algorithms. For example, VAEs or GANs can produce realistic images resembling defective products that enable the machine learning model to understand how to identify and categorize defects without needing a big dataset of actual-world malfunctioning goods. Such approach can significantly reduce costs and time needed for data collection as well as labeling processes.